Baffle grease filter and mesh grease filter are two common grease filters. They are different in structure and working principle. The following are their differences, advantages and disadvantages:

Baffle grease filter

Structure: The baffle grease filter consists of a series of metal baffles forming a closed channel. When oil fume passes through the channel, the oil droplets will be separated and collected due to wind resistance and baffles.

- Advantage:

● Baffled grease filters are an important component in managing grease and regulating exhaust ventilation in commercial kitchens. It can safely protect the exhaust port, prevent flames or flammable debris from entering the pipe, and capture grease vapor and particles to prevent them from accumulating in the ventilation system, effectively avoiding smoke pipe and ventilation system fires.

● Good separation effect: The baffle filter can effectively separate oil droplets and reduce oil smoke emissions.

● Easy to clean: The metal baffle of the baffle filter can be removed for easy cleaning and maintenance.

- Disadvantage:● Large wind resistance: Due to the existence of the baffle, the baffle filter will increase the wind resistance of the range hood system, which may require greater fan power.

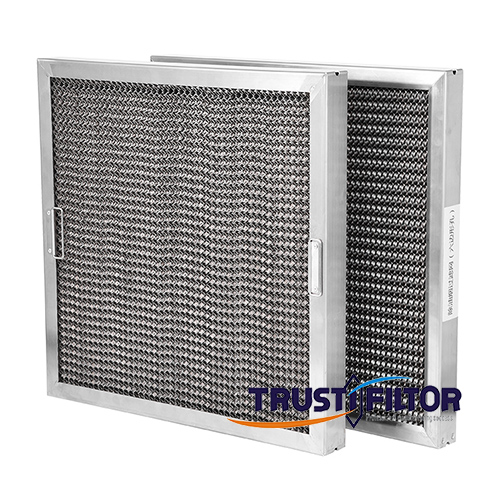

Mesh grease filter:

Mesh grease filter: The mesh grease filter usually consists of a metal mesh cover. When the oil fume passes through the mesh cover, the particles will be intercepted and collected by the mesh cover.

- Advantage:● Good ventilation: The metal mesh cover of the mesh filter will not have a significant impact on wind resistance, which is beneficial to ventilation and oil fume emission.

● Easy maintenance: The mesh cover of the mesh filter can be disassembled and cleaned for easy maintenance and cleaning.

- Disadvantage:● Relatively poor filtration effect: The filtration effect of the mesh filter on fine particles and oil droplets may not be as good as that of the baffle filter.

● High cleaning frequency: Because the mesh filter has larger filter holes, it is easy to be contaminated with oil and requires frequent cleaning and maintenance.

How to set the filter of oil fume purifier

How to set the filter of oil fume purifier

The role of ozone removal filter in air purifier

The role of ozone removal filter in air purifier

What are the industrial applications of oil fume removal filters

What are the industrial applications of oil fume removal filters

Industrial applications of ozone removal filters

Industrial applications of ozone removal filters