Kitchen grease filters are one of the first lines of defense for restaurant safety. Kitchen grease is highly flammable, so replacing and maintaining the grease filter in the restaurant is an important step in reducing the risk of kitchen grease fire.

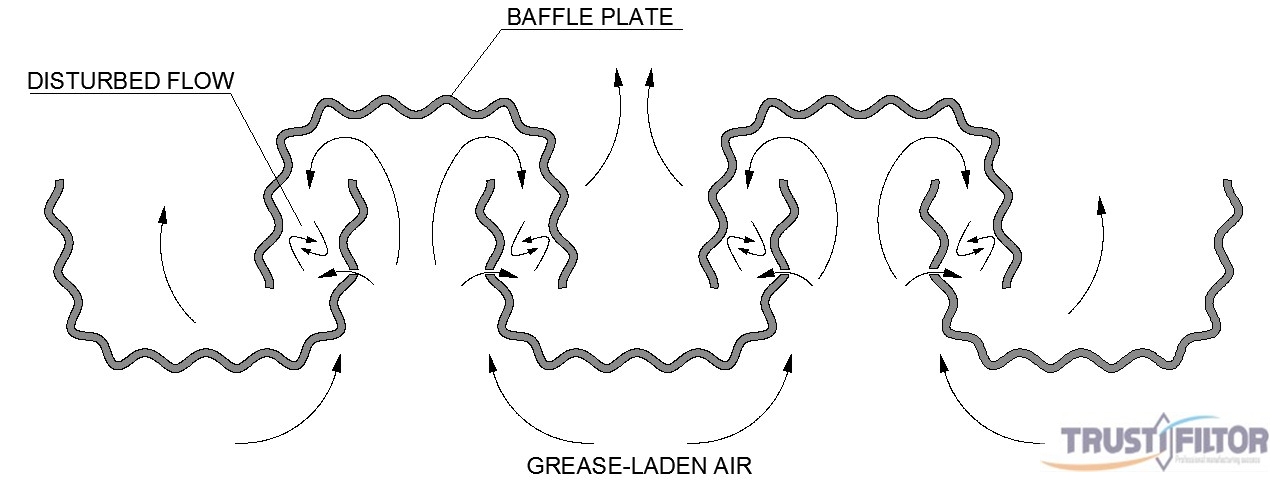

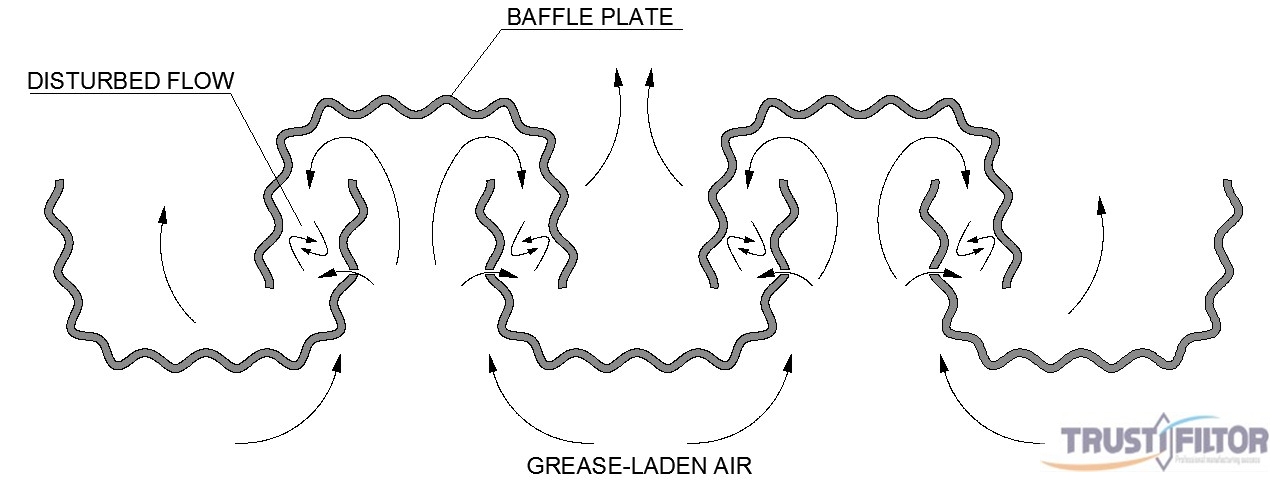

Compared to other grease filters, baffle grease filters can capture more debris, delay fires, and allow greater air circulation. They block flames better than box filters or aluminum mesh filters, and in most places, the latter no longer meets the specifications. The baffle design forces droplets filled with grease to be captured before entering the exhaust system. This means they are more likely to prevent kitchen fires and pipeline fires, thereby saving buildings and lives.

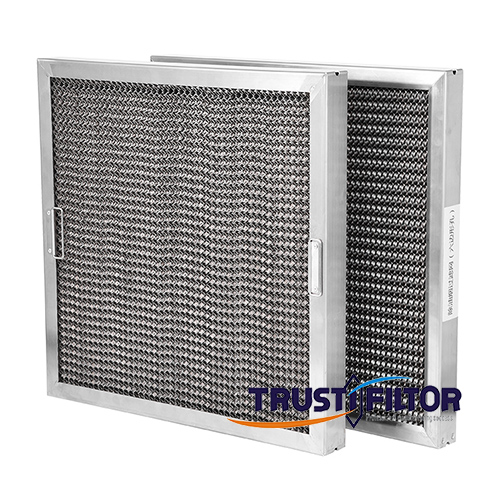

The baffle grease filter developed and produced by Trusty with UL1046 certification in the United States, has the following characteristics:

1> Efficient, curved wave design; Effectively increasing the frequency of collision between oil fumes and the filter screen and the surface area of the filter surface, thereby improving the oil removal efficiency of the system and reducing energy consumption.

2> Safe and scratch resistant design; The punching direction of the entire filter hole is inward, and the metal edge is specially treated to ensure no scratches during installation and maintenance.

3> Flame retardant, unique turbulence hole design; The turbulence hole accelerates the wind speed, and the airflow carries away the surrounding heat. The pressure in the airflow zone sharply decreases, and the flame lacks temperature and oxygen, naturally extinguishing. It is the specific application of the "candle blowing effect".

How to set the filter of oil fume purifier

How to set the filter of oil fume purifier

The role of ozone removal filter in air purifier

The role of ozone removal filter in air purifier

What are the industrial applications of oil fume removal filters

What are the industrial applications of oil fume removal filters

Industrial applications of ozone removal filters

Industrial applications of ozone removal filters