Usually there are many types of deozone filters, such as aluminum honeycomb deozone filters, ceramic base deozone filters, industrial sponge deozone filters, etc., which factors be related to one-time removal efficiency of the ozone filter?

The one-time removal efficiency of the ozone filter is mainly related to the contact area and the contact time. The larger the contact area between the ozone and the filter screen and the longer the contact time, the higher the one-time removal efficiency, and vice versa. Aluminum honeycomb is the most common substrate for ozone removal filters. Let's take aluminum honeycomb ozone filter as an example.

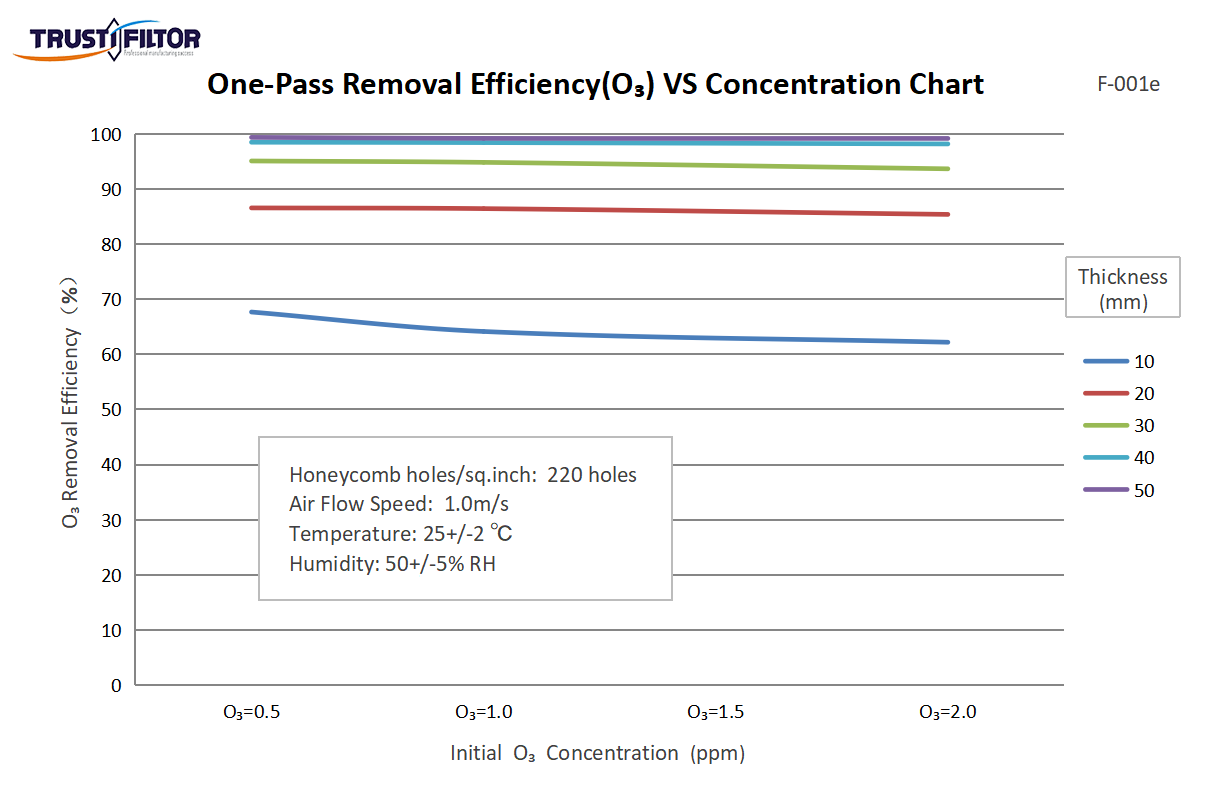

*Initial concentration of ozone. the lower the initial concentration of ozone, the higher the one-time removal efficiency;

*Holes of aluminum honeycomb. refers to the number of holes in the honeycomb within one square inch, usually with a hole counter. Aluminum honeycomb with the same unit area, common specifications: 100 holes, 220 holes, 350 holes, 600 holes, 900 holes, the more the number of holes, the larger the contact area;

*Aluminum honeycomb thickness. common thickness:10mm, 20mm, 30mm, 40mm, 50mm, the thicker the aluminum honeycomb thickness, the larger the contact area;

*Wind speed. The wind speed used in the laboratory is 1m/s. The smaller the wind speed, the longer the contact time between ozone and the catalyst on the surface of the filter, and the higher the one-time filtration efficiency;

In a word, under the premise of constant temperature and humidity in the use environment, the lower the initial concentration of ozone,the smaller the wind speed, the higher the one-time removal efficiency; the more aluminum honeycomb holes, the thicker the thickness, the larger the contact area, and the higher the one-time filtration efficiency . If you have other questions, welcome to consult us.

How to set the filter of oil fume purifier

How to set the filter of oil fume purifier

The role of ozone removal filter in air purifier

The role of ozone removal filter in air purifier

What are the industrial applications of oil fume removal filters

What are the industrial applications of oil fume removal filters

Industrial applications of ozone removal filters

Industrial applications of ozone removal filters